Used Paint and Powder Coating Booths

s

$1,000,000

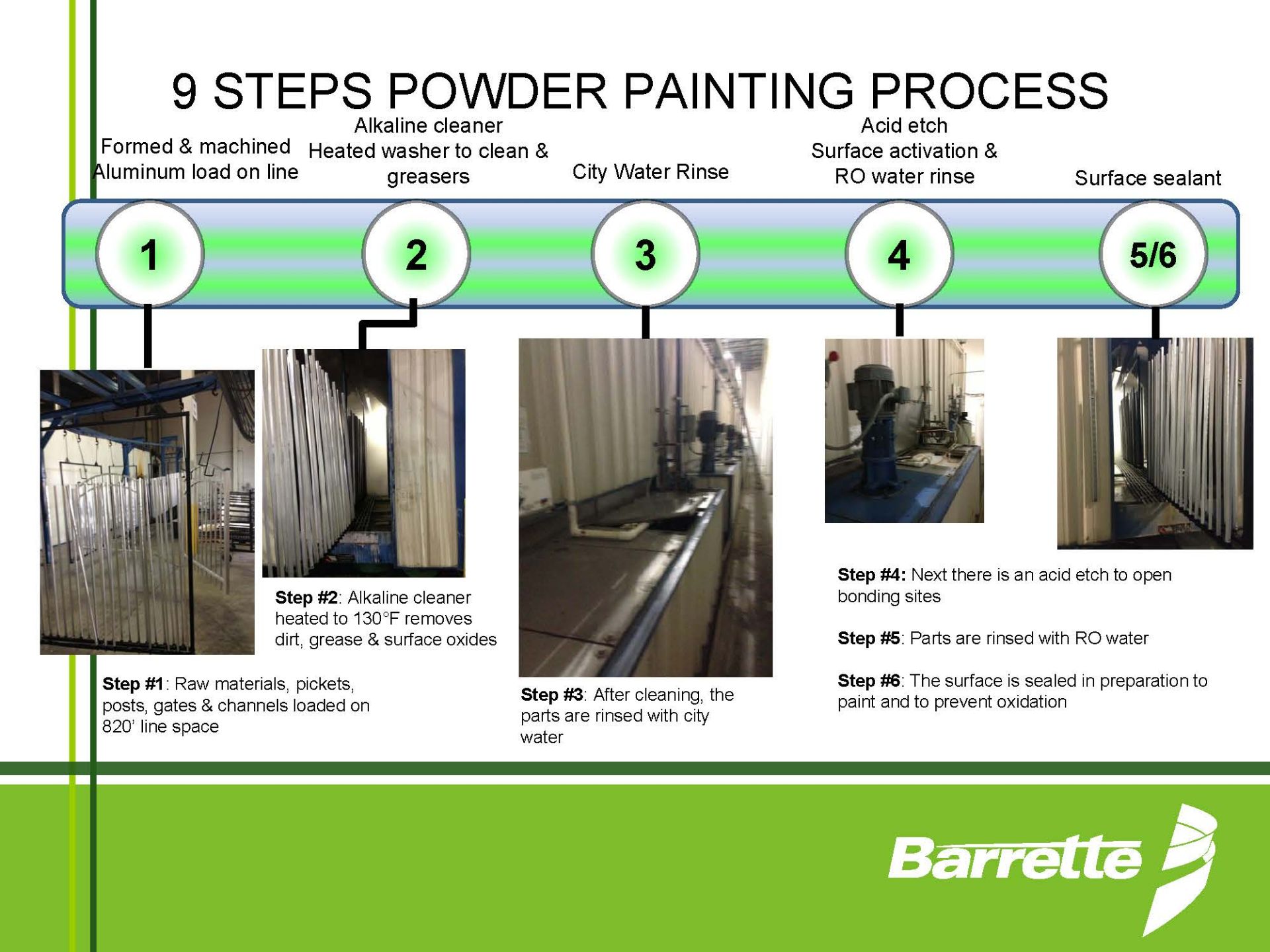

Complete 9-Steps Powder Coating Paint Line

User Manuals, Documentation and Drawings (Manuals, documentation and drawings available upon purchase of paint line.

Original system’s design, general components descriptions, and criteria.

1.6 Million Dollar Replacement Cost!

USED

Great Deal!

ITEM:

1234

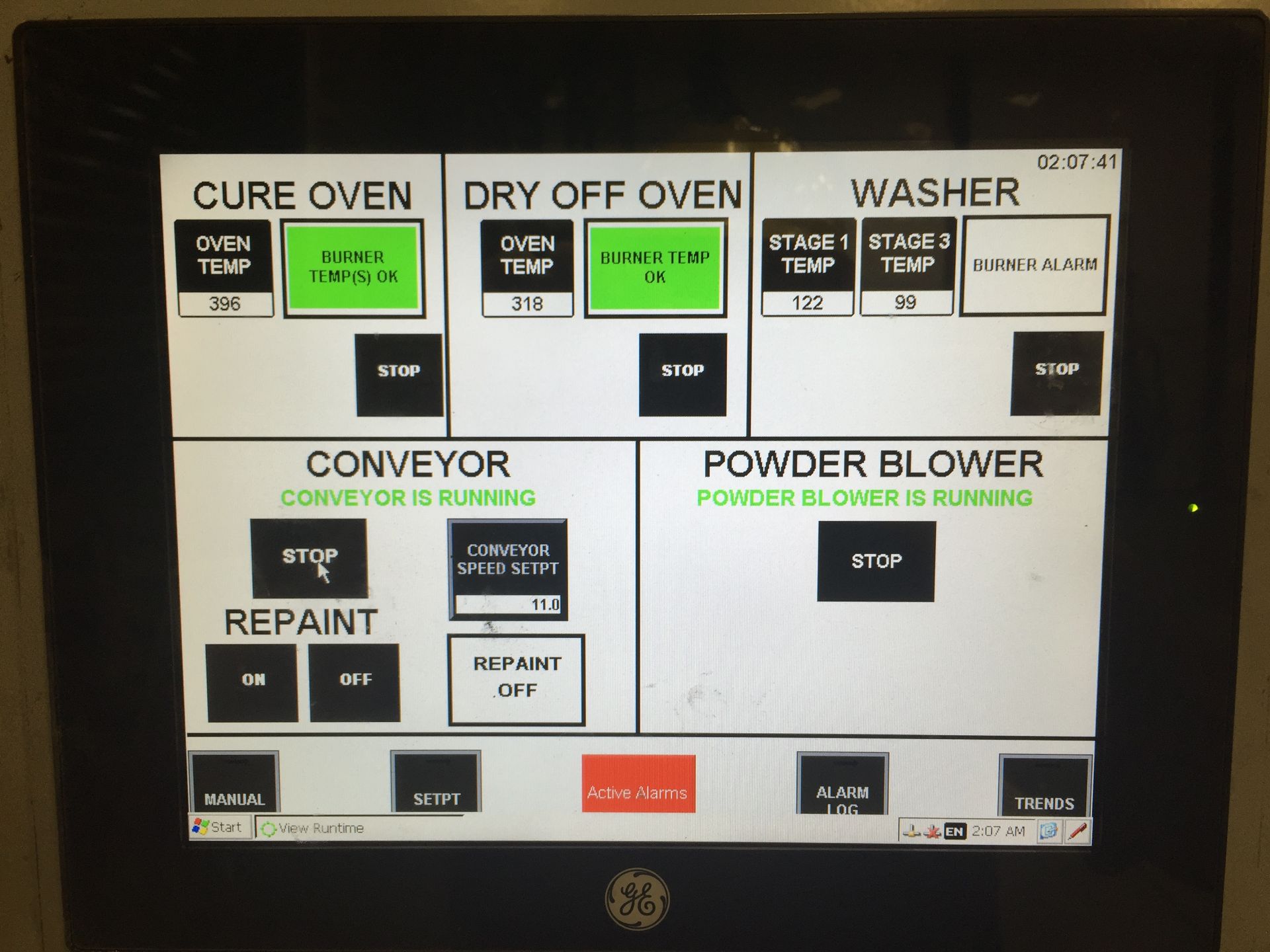

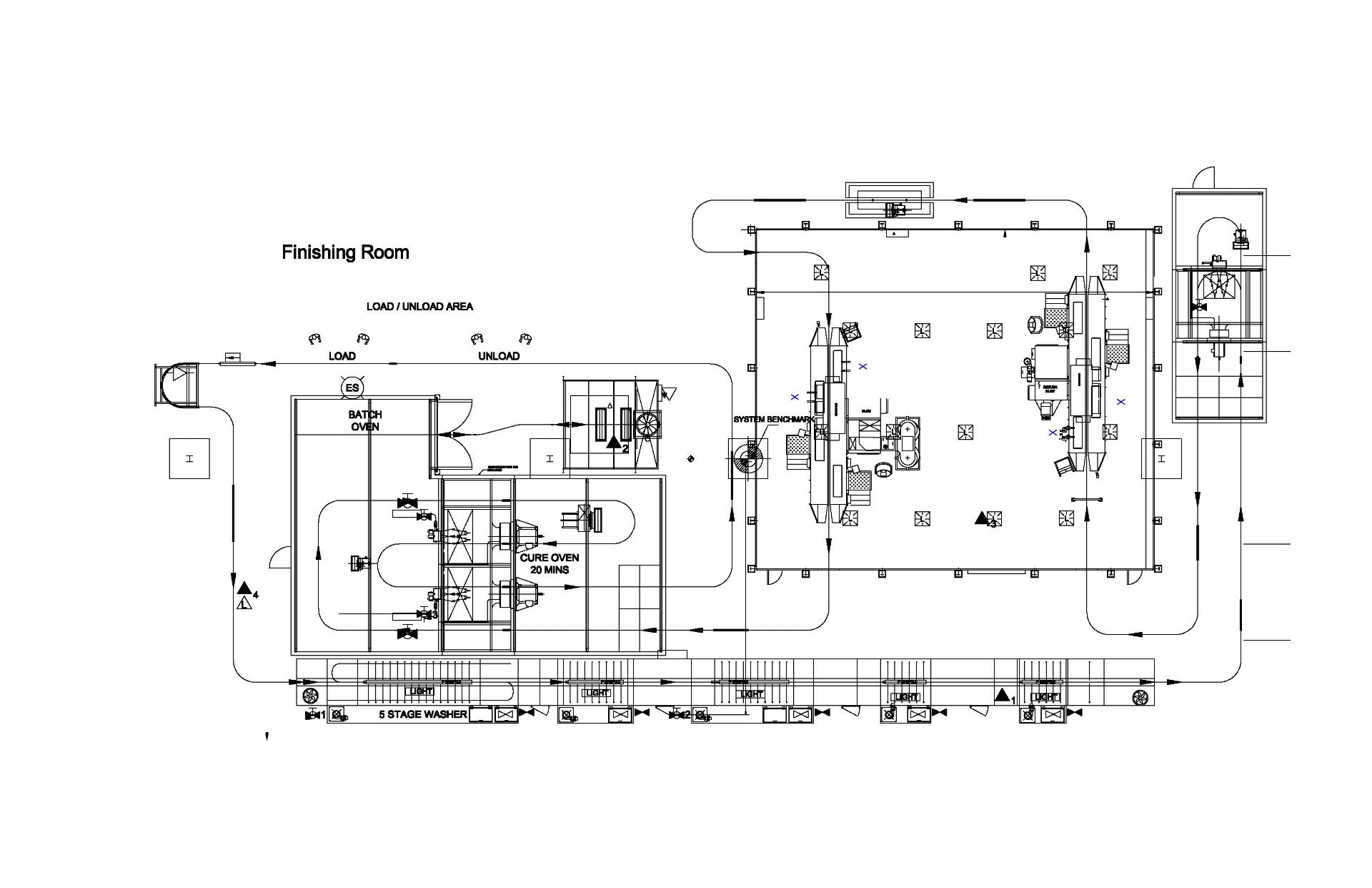

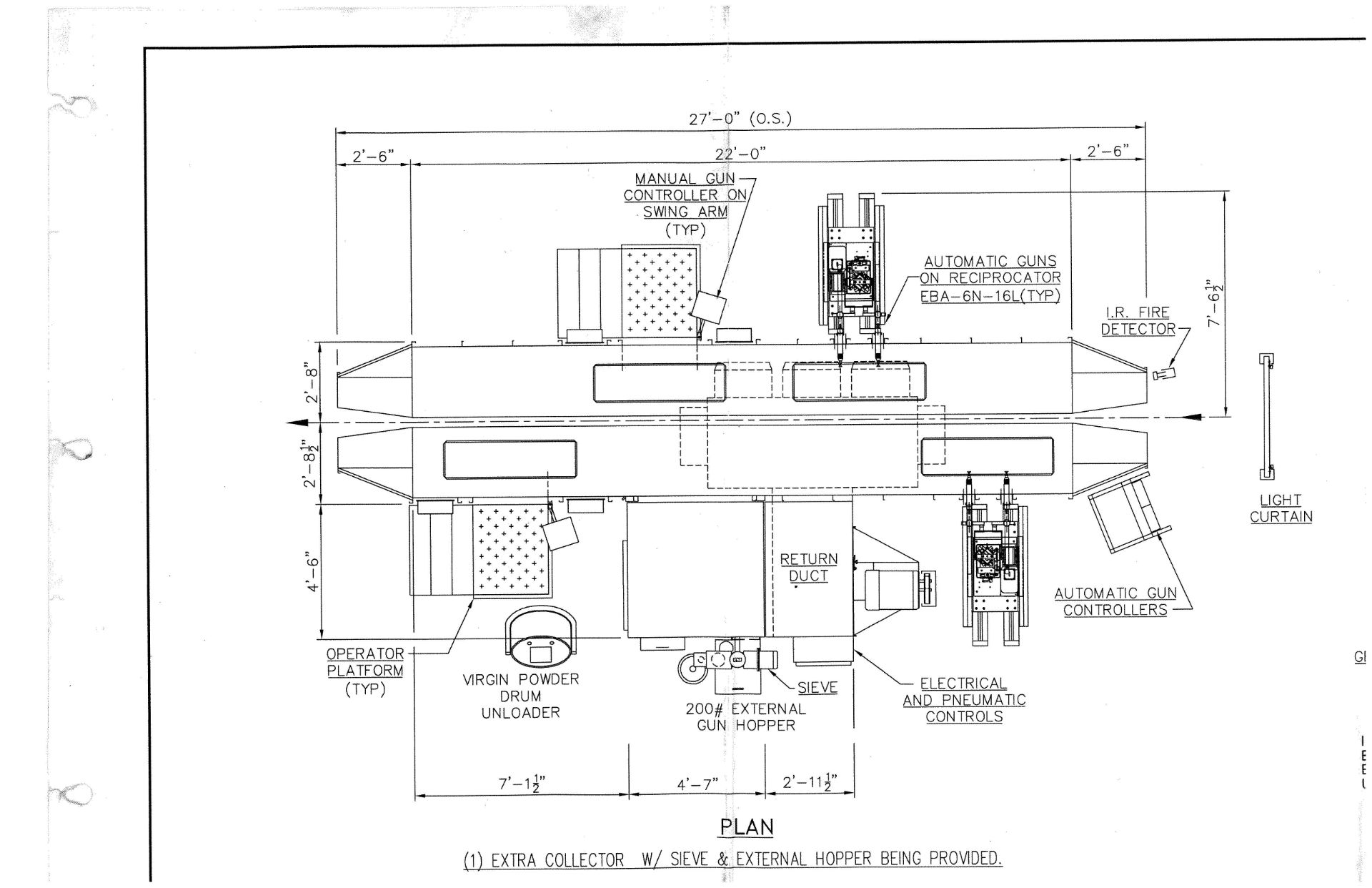

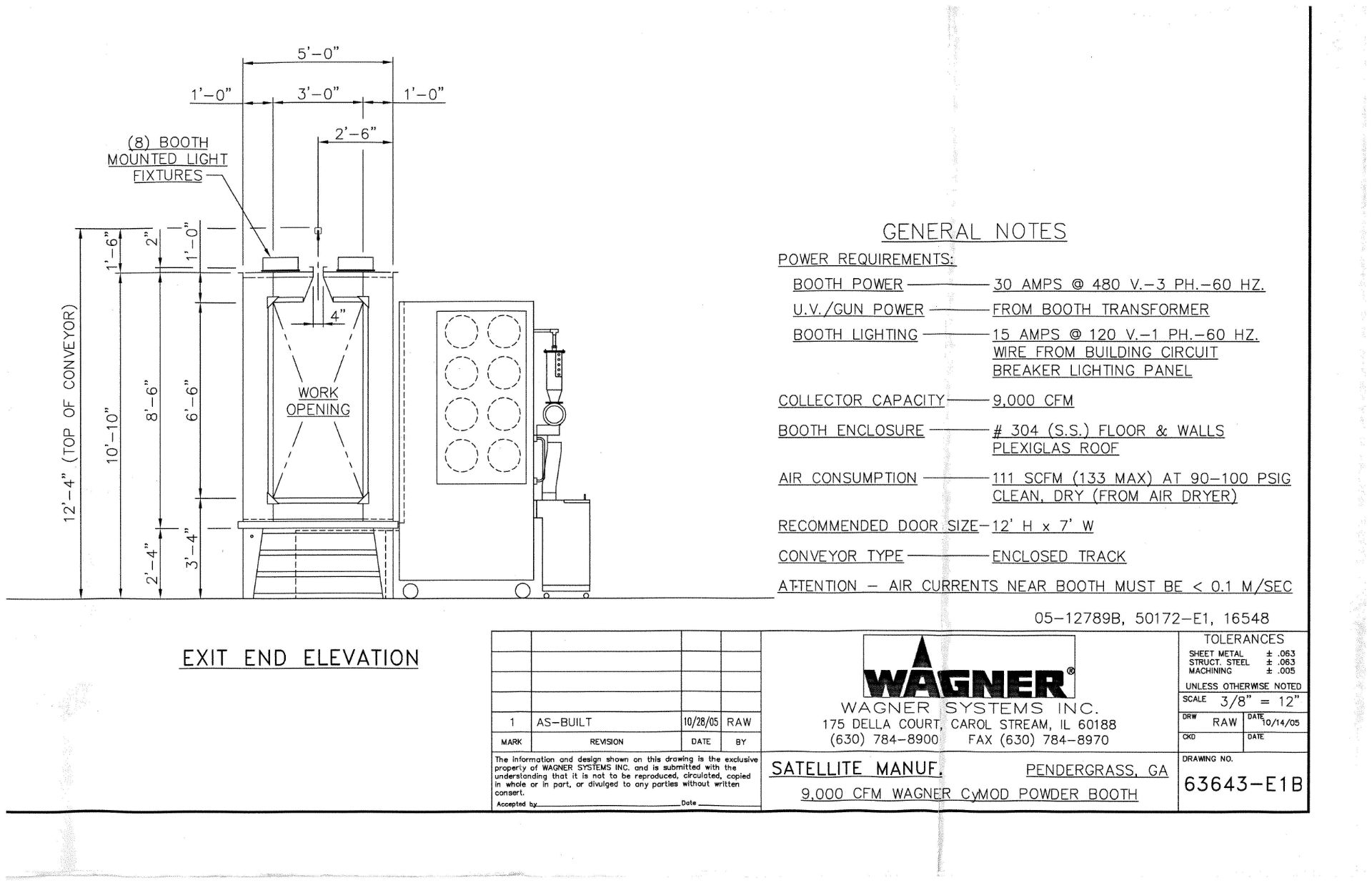

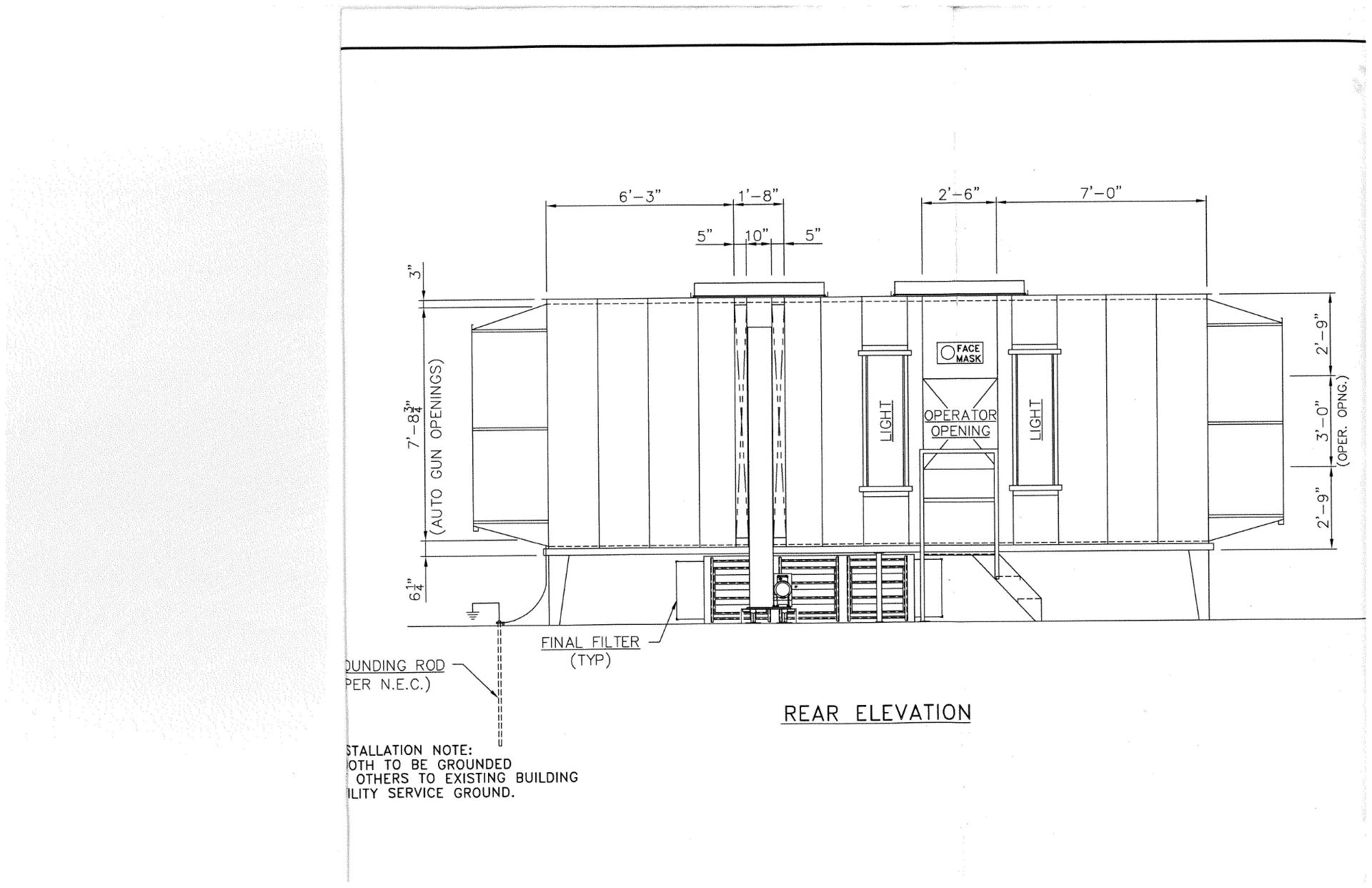

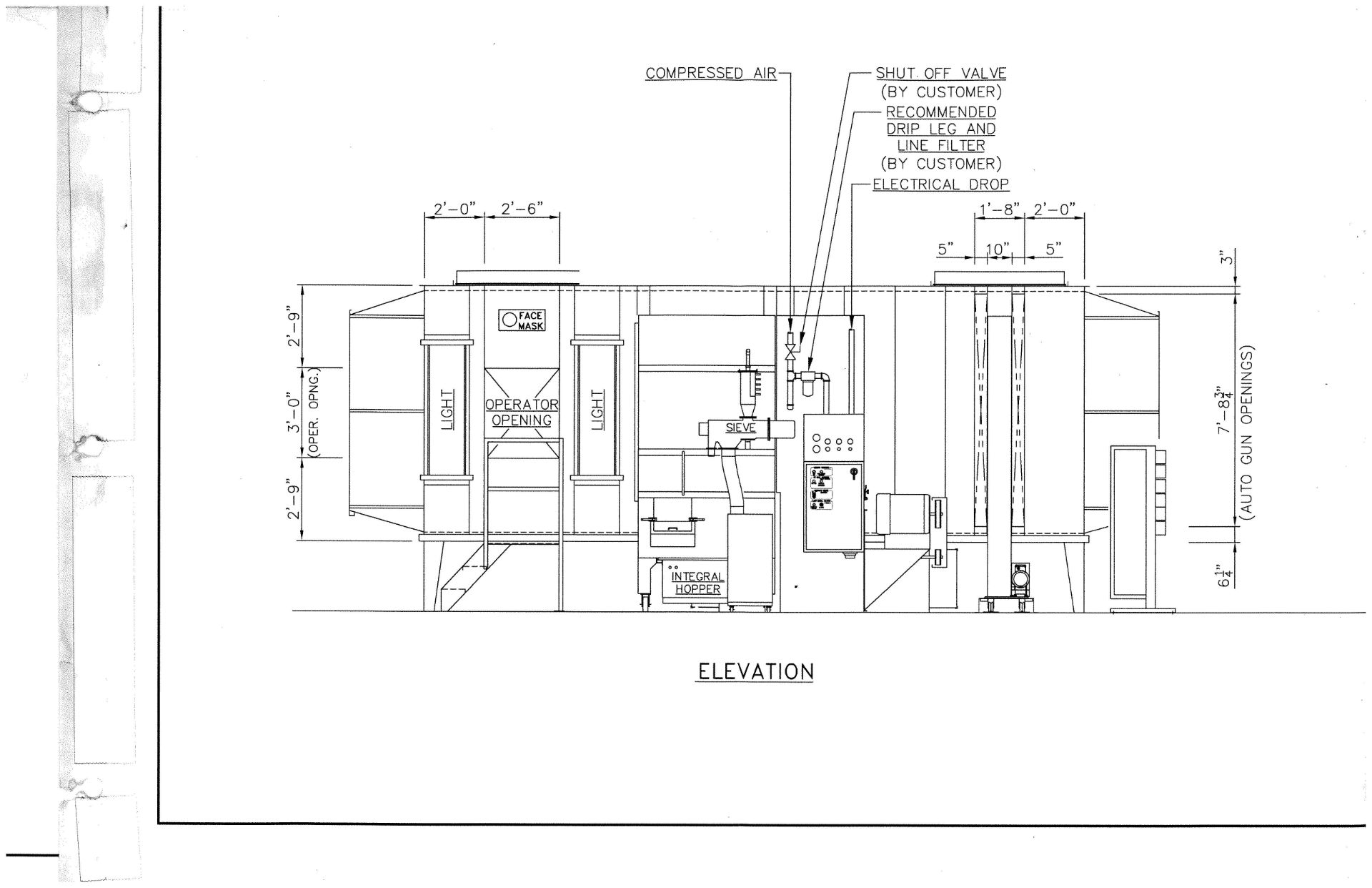

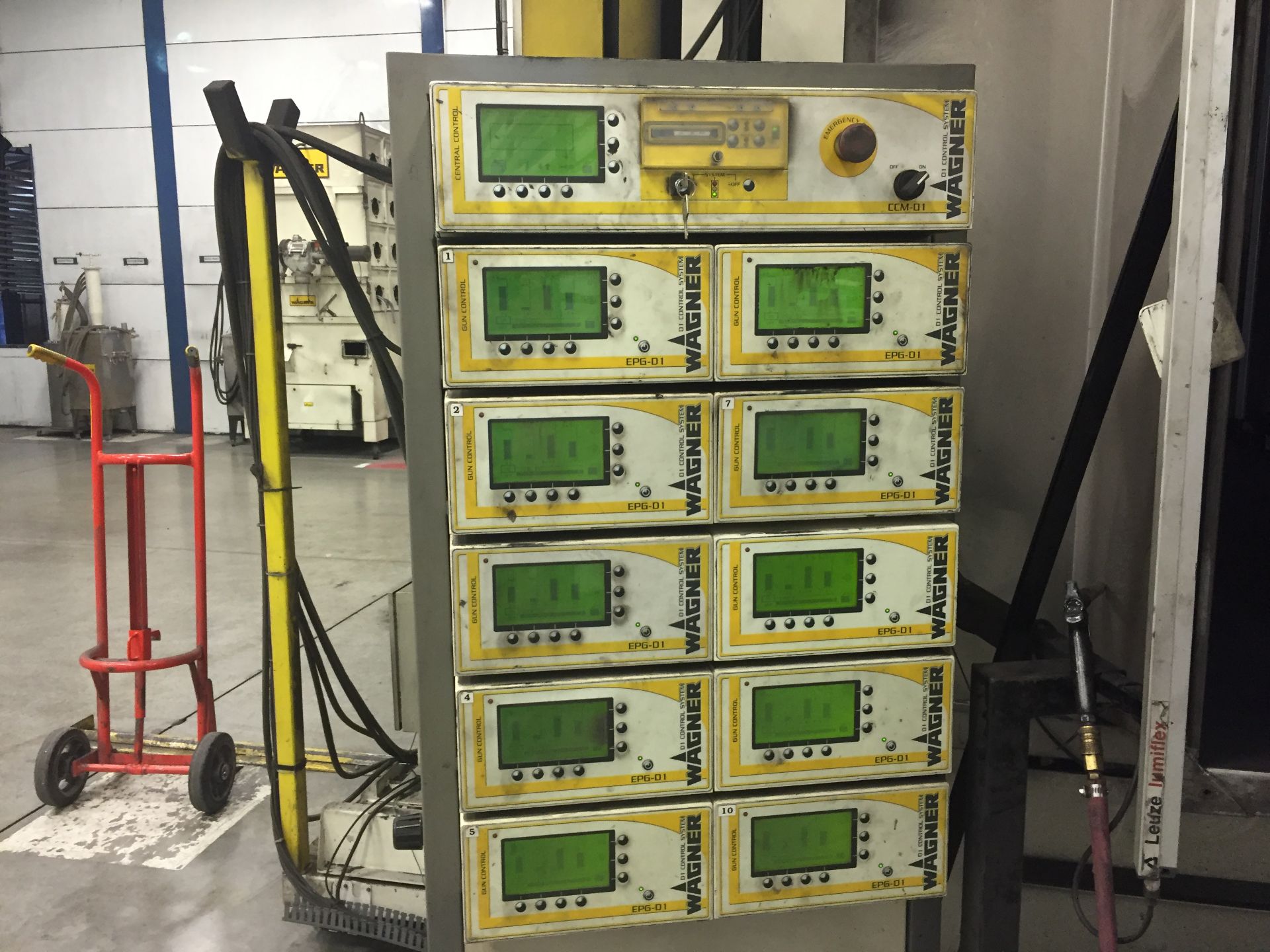

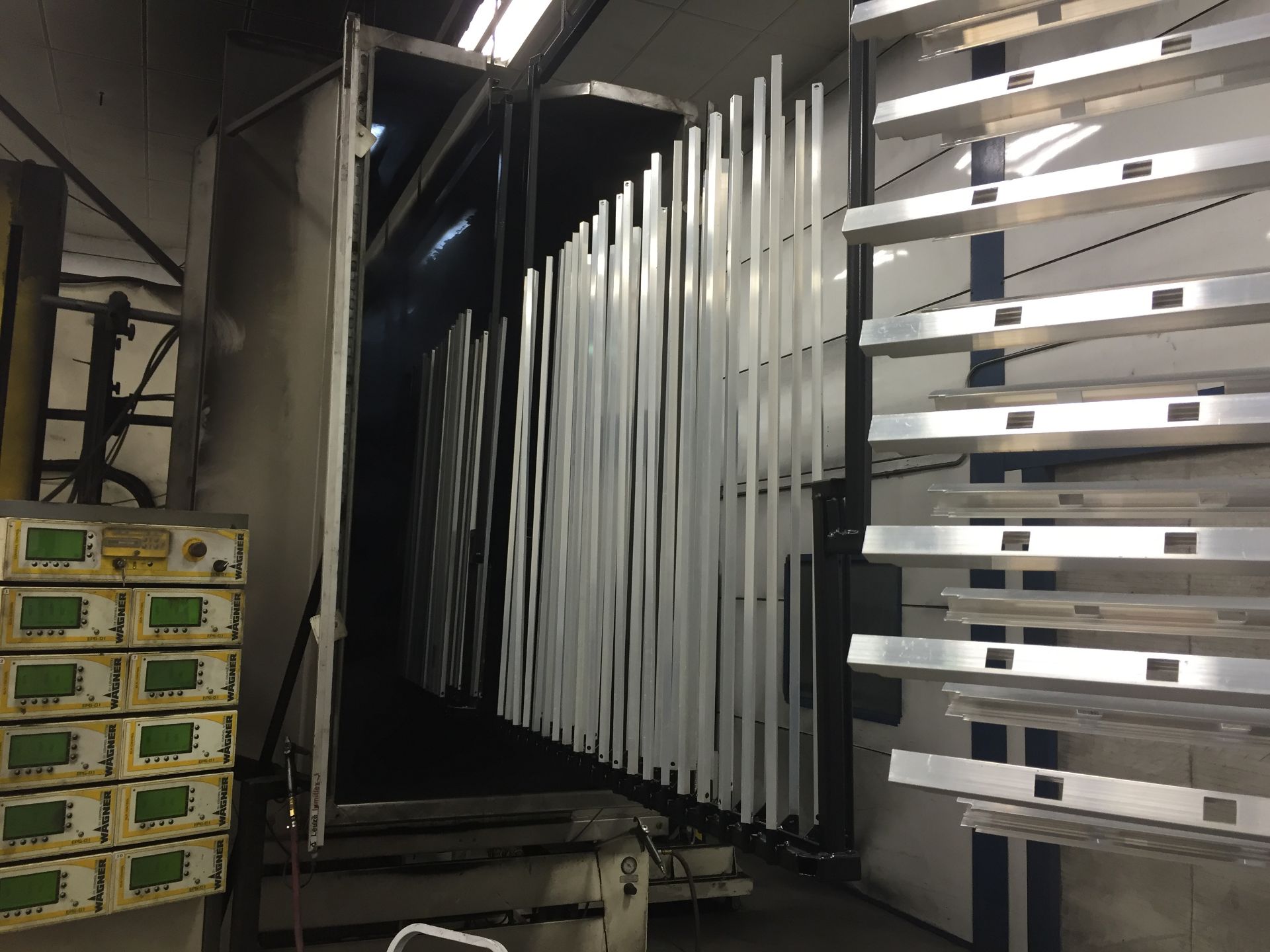

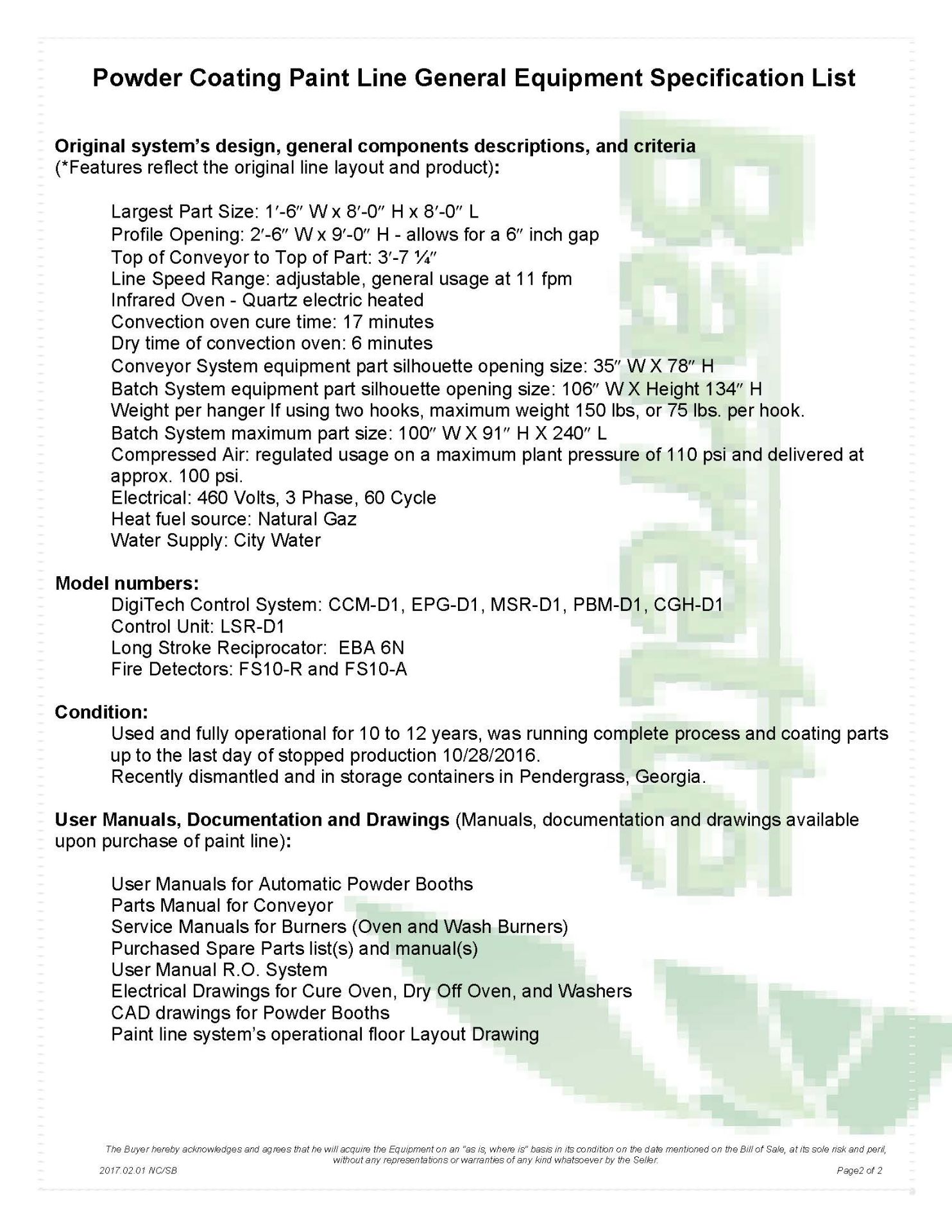

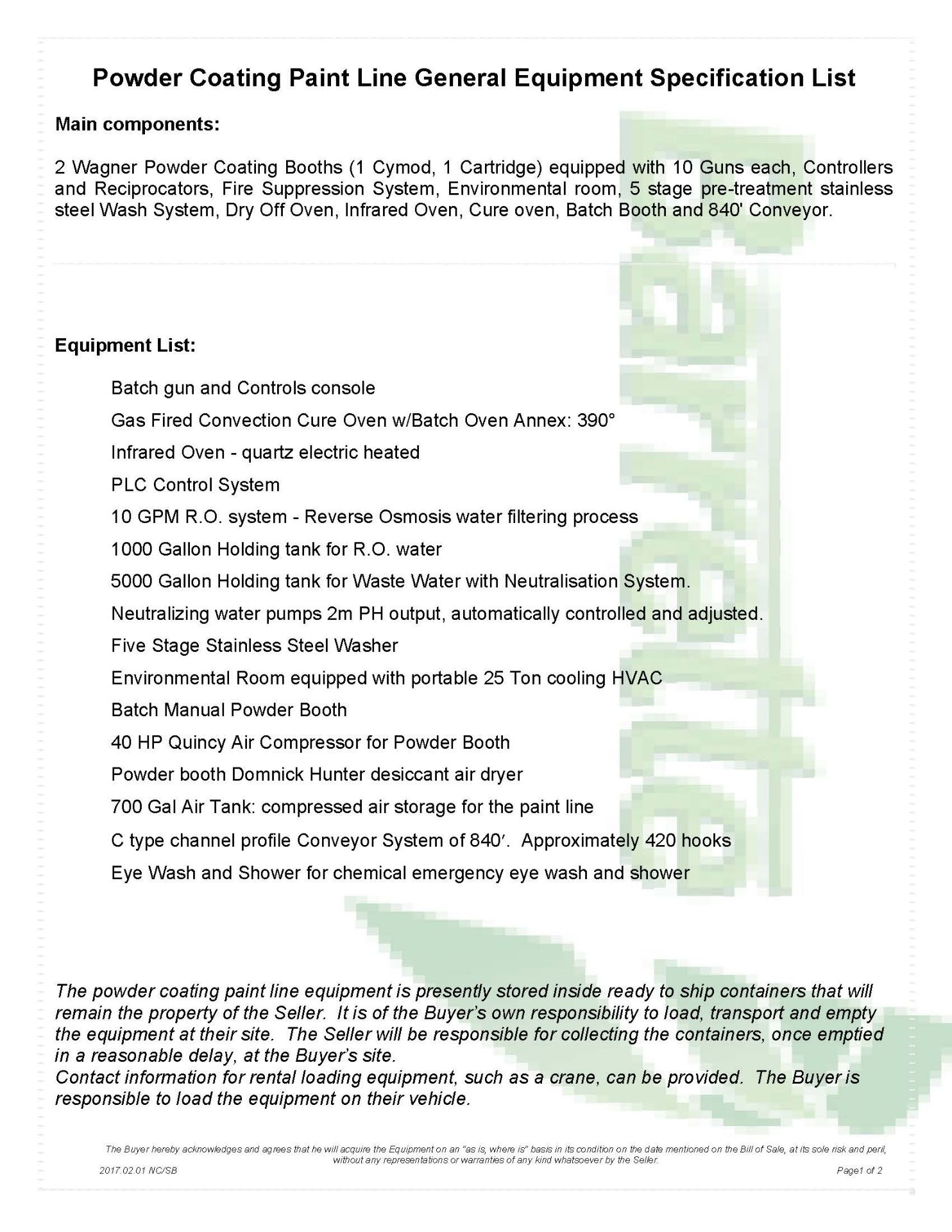

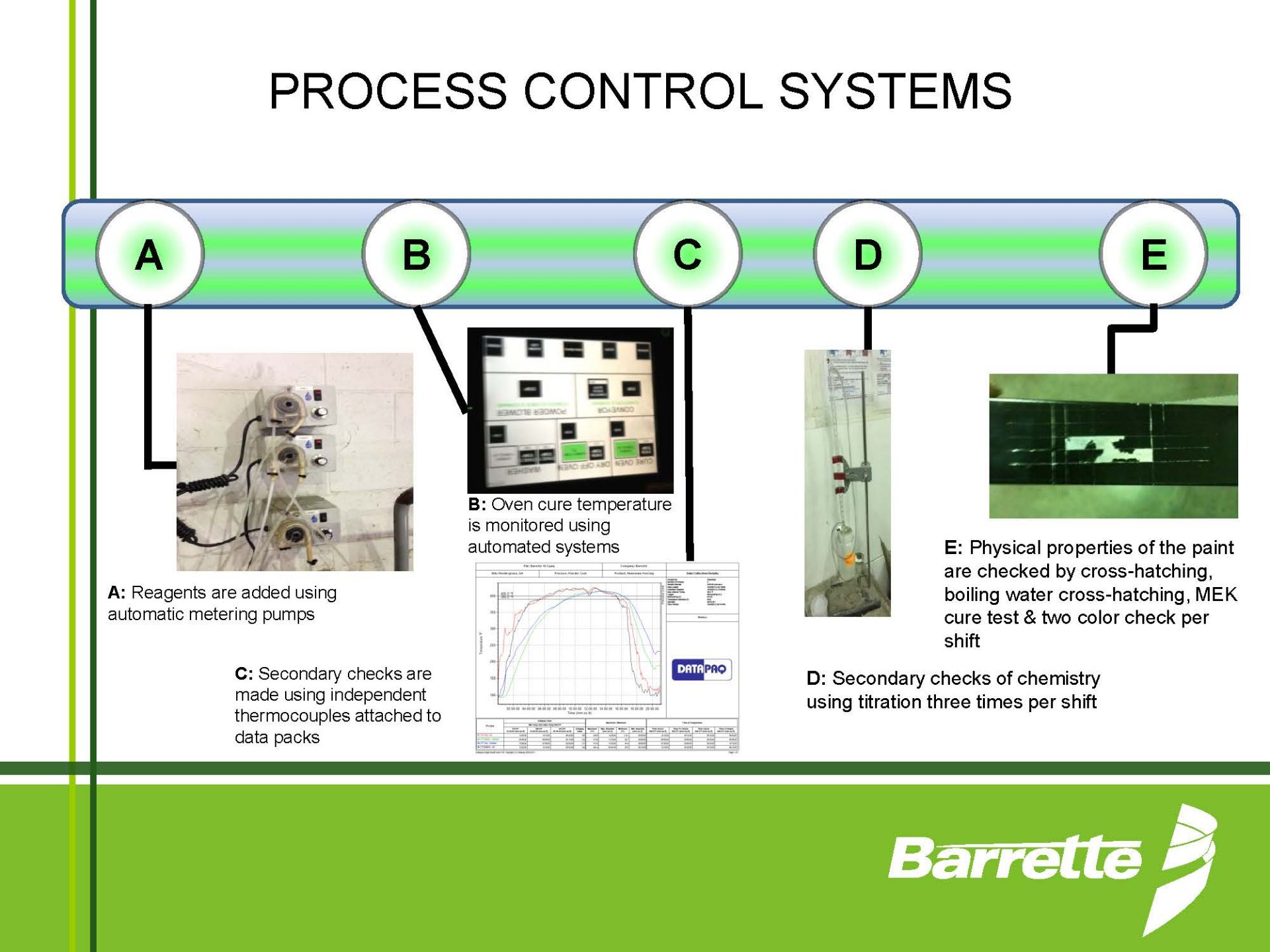

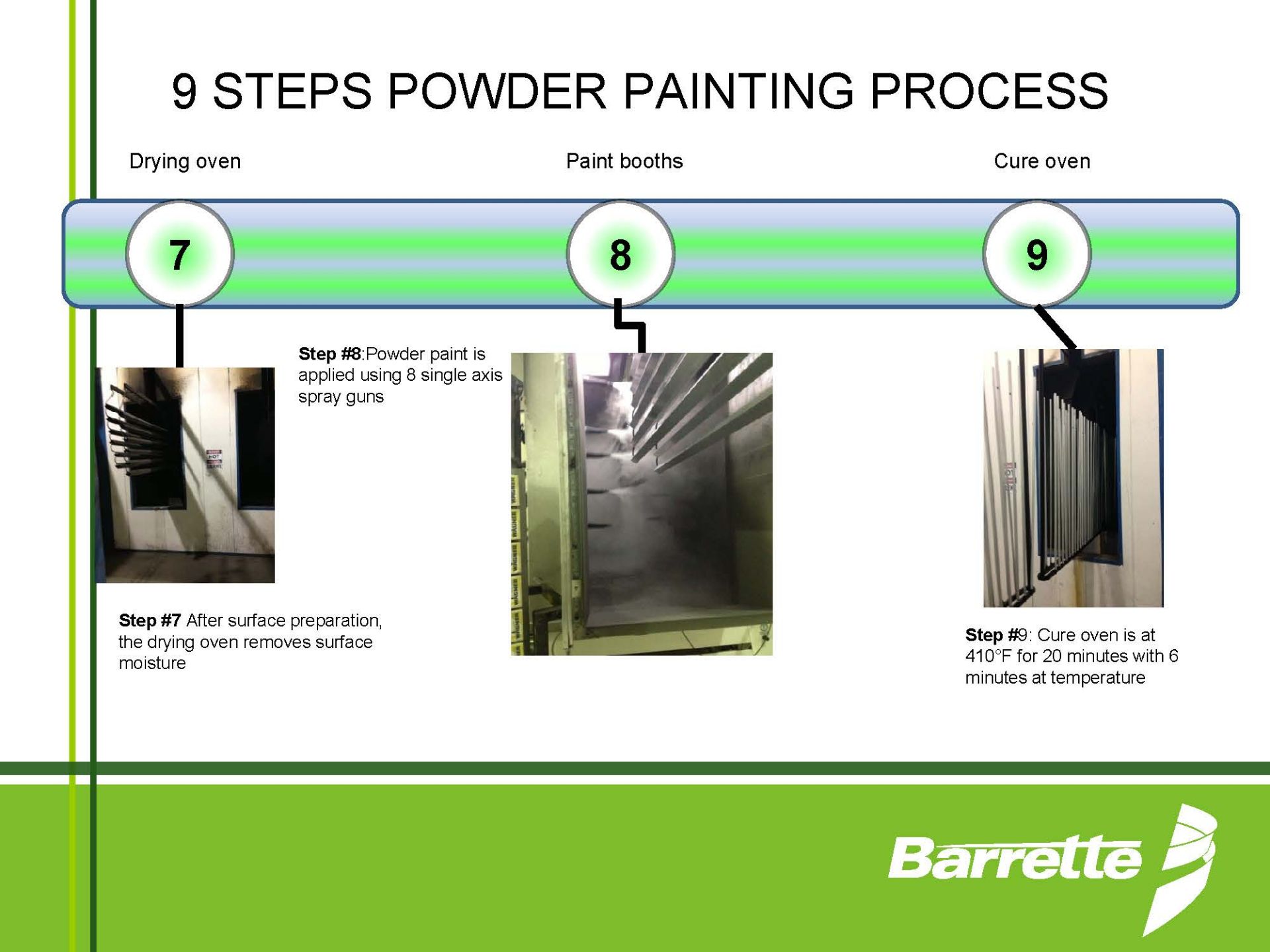

REPLACEMENT COST OF 1.6 MILLION DOLLAR COMPLETE 9-STEPS POWDER COATING PAINT LINE COMPRISING OF: Main components: 2 Wagner Powder Coating Booths (1 Cymod, 1 Cartridge) equipped with 10 Guns each, Controllers and Reciprocators, Fire Suppression System, Environmental room, 5 stage pre-treatment stainless steel Wash System, Dry Off Oven, Infrared Oven, Cure oven, Batch Booth and 840' Conveyor. Equipment List: - Batch gun and Controls console - Gas Fired Convection Cure Oven w/Batch Oven Annex: 390° - Infrared Oven - quartz electric heated - PLC Control System - 10 GPM R.O. system - Reverse Osmosis water filtering process - 1000 Gallon Holding tank for R.O. water - 5000 Gallon Holding tank for Waste Water with Neutralisation System. - Neutralizing water pumps 2m PH output, automatically controlled and adjusted. - Five Stage Stainless Steel Washer - Environmental Room equipped with portable 25 Ton cooling HVAC - Batch Manual Powder Booth - 40 HP Quincy Air Compressor for Powder Booth - Powder booth Domnick Hunter desiccant air dryer - 700 Gal Air Tank: compressed air storage for the paint line - C type channel profile Conveyor System of 840¢. Approximately 420 hooks - Eye Wash and Shower for chemical emergency eye wash and shower Original system’s design, general components descriptions, and criteria (*Features reflect the original line layout and product): - Largest Part Size: 1¢-6² W x 8¢-0² H x 8¢-0² L - Profile Opening: 2¢-6² W x 9¢-0² H - allows for a 6² inch gap - Top of Conveyor to Top of Part: 3¢-7 ¼² - Line Speed Range: adjustable, general usage at 11 fpm - Infrared Oven - Quartz electric heated - Convection oven cure time: 17 minutes - Dry time of convection oven: 6 minutes - Conveyor System equipment part silhouette opening size: 35² W X 78² H - Batch System equipment part silhouette opening size: 106² W X Height 134² H - Weight per hanger If using two hooks, maximum weight 150 lbs, or 75 lbs. per hook. - Batch System maximum part size: 100² W X 91² H X 240² L - Compressed Air: regulated usage on a maximum plant pressure of 110 psi and delivered at approx. 100 psi. - Electrical: 460 Volts, 3 Phase, 60 Cycle - Heat fuel source: Natural Gaz - Water Supply: City Water Model numbers: DigiTech Control System: CCM-D1, EPG-D1, MSR-D1, PBM-D1, CGH-D1 Control Unit: LSR-D1 Long Stroke Reciprocator: EBA 6N Fire Detectors: FS10-R and FS10-A Condition: Used and fully operational for 10 to 12 years, was running complete process and coating parts up to the last day of stopped production 10/28/2016. Recently dismantled and in storage containers in Pendergrass, Georgia. User Manuals, Documentation and Drawings (Manuals, documentation and drawings available upon purchase of paint line): - User Manuals for Automatic Powder Booths - Parts Manual for Conveyor - Service Manuals for Burners (Oven and Wash Burners) - Purchased Spare Parts list(s) and manual(s) - User Manual R.O. System - Electrical Drawings for Cure Oven, Dry Off Oven, and Washers - CAD drawings for Powder Booths - Paint line system’s operational floor Layout Drawing - Purchased Spare Parts list(s) and manual(s) - User Manual R.O. System - Electrical Drawings for Cure Oven, Dry Off Oven, and Washers - CAD drawings for Powder Booths - Paint line system’s operational floor Layout Drawing The powder coating paint line equipment is presently stored inside ready to ship containers that will remain the property of the Seller. It is of the Buyer’s own responsibility to load, transport and empty the equipment at their site. The Seller will be responsible for collecting the containers, once emptied in a reasonable delay, at the Buyer’s site. Contact information for rental loading equipment, such as a crane, can be provided. The Buyer is responsible to load the equipment on their vehicle.